Metal powder injection molding technology is developed from ceramic powder injection molding technology, it is a new type of powder metallurgy near net shape technology. Metal powder injection molding technology, production processes are: metal powder mixed with binder - granulating - injection molding - degreasing - sintering - processing - the final product.

Metal Powder Particle and Manufacturing Methods Influencing on MIM technology

With increasing car ownership in our country, the production of brake pad is also increasing year by year. Brake pads is the key components of train brake system. The quality of the high-speed rail brake pads is directly related to the train speed can slow down and stop in time, called "the patron saint of life".

Powder metallurgy technology is the key to automobile weight loss and the energy conservation and environmental protection

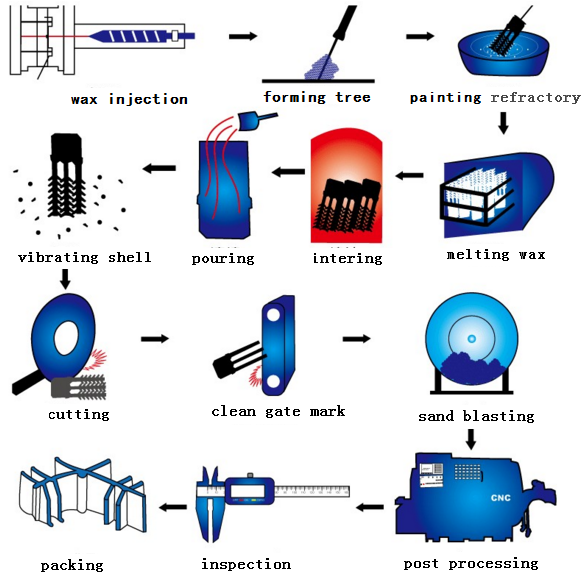

Investment casting also called lost_wax casting. This kind of casting process can produce sophisticated parts that close to the final product shape,metal parts or fine arts and crafts while don't need or rarely need machining.It is a kind of near net shape Metal liquid forming technology, and is widely applied.

In recent years metal injection molding technology is mainly developing in two directions: The expansion of the material system. High reliability of production equipment developed to meet the unique binder and degreasing technology. It has the following characteristics:

New Products You may like

Sintering MIM Electronic Components Earphone Shell Metal Parts read more

Stainless Steel Sintered Powder Metallurgy Mechanical Brass Gear read more

Stainless Steel Sintered Powder Metallurgy Metal Gears read more

Stainless Steel Sintered Powder Metallurgy Metal Gears read more

Stainless Steel Sintered Powder Metallurgy Mechanical Gear Ring read more

Copyright © Harber Industrial Limited All Rights Reserved. | mechanical gear ring | mim parts | powder metallurgy gears | China MIM | Sitemap

IPv6 network supported

Send A Message

Send A MessageIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.